I finally decided to upgrade my Synology NAS to the latest release and encountered several issues. One of them was that JDownloader had become very slow with a high cpu load. As the Oracle JAVA runtime isn’t supported (yet?) on DMS7 version you’ll have to switch to open JDK as the instructions indicate. Instead of a re-installation, I decided to keep my current JDownloader installation which seemed to work reasonably well until I started to download something which was very slow.

After some searching I found out that you’ll need to do a re-installation as the installation procedure installs a different version when using the openjdk runtime. After installation you could just copy the CFG folder to keep all your settings…. I compared the folders and the jar files where indeed different. However… the download speed was as slow as it was before 😦

This was caused because I used the DSM integrated runtime (interpreter!) instead of the one found in /volume1/@appstore/java-installer/bin/java

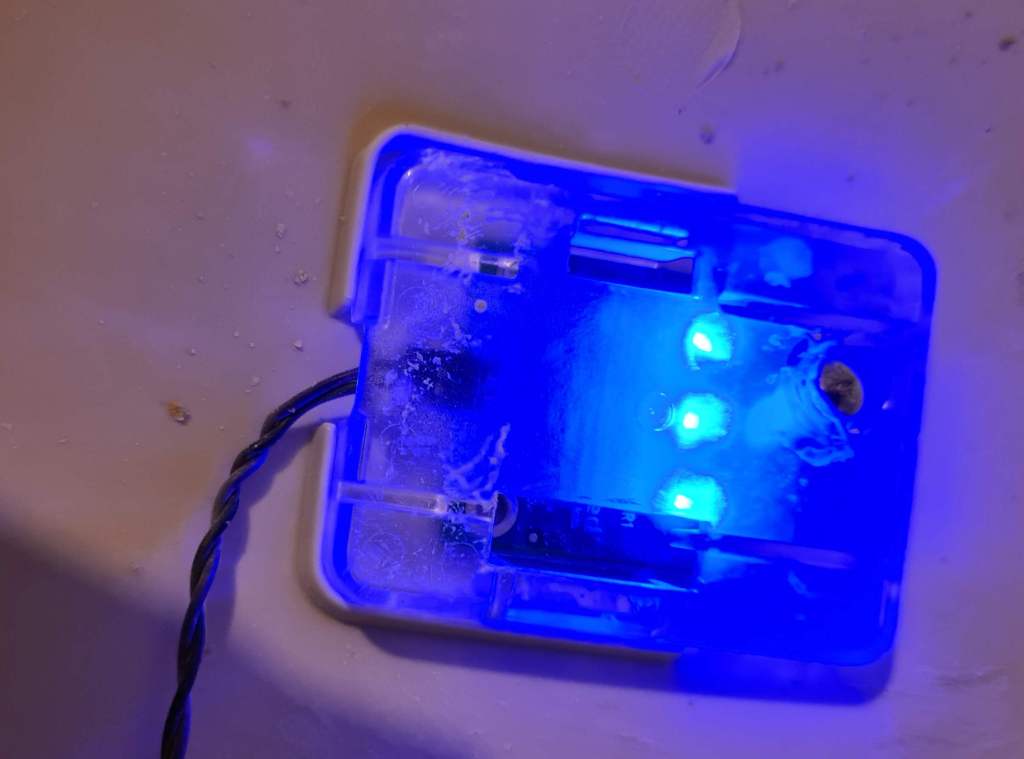

So check the JDownloader settings section to see if you’re running the wrong (=zerovm) version.